Bowe Shredder Rotors

Bowe Machine Company has been manufacturing Auto Shredder Rotors for over 50 years. We have machined and built over 500 new Rotors and rebuilt more than 50.

With the objective to build the World’s Best Shredder Rotors, Bowe stays one step ahead of the Industry by revolutionizing not just how our Rotors are designed and manufactured, but also by working directly with the steel mills to develop new lines of steel used.

As part of the engineering process, we utilize FEA (Finite Element Analysis) and Solid Modeling, not “guess work,” to create Rotor designs that have proven to be more robust and capable of lasting longer than any other Rotor Manufacturer.

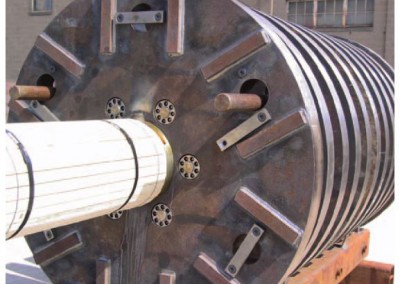

160,000 lb. Disc Rotor shipping out on a 130-foot-long truck

We recently completed an expansion project, adding 32,000 square feet of machining and assembly space. Our new building has two bays with a 40-ton and a 10-ton crane on each side. All but the largest of rotors are easily moved from the assembly area and loaded directly onto a truck inside the building, eliminating the need for hiring an outside crane service. The building also features a storage pit which will hold up to 12 rotor shaft forgings inhouse.

Rebuilt Rotors

All Bowe rotors are designed to be rebuilt by reusing the existing rotor shaft and spacers, saving you on your next rotor. Once we receive the used rotor, we remove the worn discs and manufacture new ones, re-assemble the rotor, and ship the rebuilt rotor back to you.